-

Hello! I am the Oriental ChatBot. Just let me know what you need, and I will be happy to help.

Hello! I am the Oriental ChatBot. Just let me know what you need, and I will be happy to help.

-

Choose your Language preference.

Choose your Language preference.

-

Saudi Arabia's MGS project accelerates progress, with multiple indicators setting new records

2025-06-12On April 23rd, the first joint construction task of the main pipeline of the 6th and 7th sections of the largest-diameter oil and gas pipeline project - the MGS Phase III Pipeline Project in Saudi Arabia, undertaken by the company's affiliated Petroleum Engineering Construction company, was successfully completed, marking the official start of the pipeline joint and backfilling work for this project.

Facing difficulties such as heavy production and operation tasks and relatively scarce resources, the Saudi MGS project department of the company, on the one hand, vigorously promotes advanced equipment and technologies such as vacuum pipe hanging machines and welding laser video surveillance, and on the other hand, implements an integrated management model and flexibly adjusts the construction arrangements during Ramadan, laying a solid foundation for the efficient advancement of the project.

With the conclusion of the Eid al-Fitr holiday for Saudi Muslims, the project team entered an "accelerated mode", taking the welding of the main line as the core, closely coordinating the upstream and downstream processes, conducting tracking non-destructive testing, strictly controlling the welding quality, implementing quota assessment and fulfilling it the following month, effectively stimulating the enthusiasm of employees for work.

During the critical period of the project's breakthrough, the project team actively coordinated materials, ensured sufficient reserves of construction resources, and closely cooperated with the technical studio to promptly solve on-site problems. After seven days of arduous efforts, the first automatic welding unit completed 160 welds, with a one-time welding qualification rate of 100%, setting a new historical record for the company's overseas large-diameter long-distance oil and gas pipeline projects. It quickly sparked a competitive craze of "learning from each other, catching up, helping each other and surpassing".

In the scorching desert atmosphere, the entire project line closely cooperated, achieving seamless connection in pipe laying, assembly, welding and other links. The daily construction of a single unit for trench excavation and pipe laying exceeded 600 meters. The automatic welding units No. 2 and No. 3 were not lagging behind, respectively achieving 24 and 20 welds in a single day, pressing the "accelerator" for the project construction with practical actions.

Next, the project department will adhere to the principle of "safety first and quality priority", continuously strengthen safety and compliance management, enhance the coordinated advancement of each process, accelerate the formation of large-scale assembly line operations, and promote the high-quality operation of the project.

-

CPECC undertook the construction of the Saudi Aramco MGS Phase III project formal ignition welding

2024-12-06On November 30, the 6-package and 7-package projects of Saudi Aramco MGS Phase III pipeline project group, which were constructed by CPECC, were formal ignition welding, marking that the project officially entered the key stage of main engineering construction.

The pipeline length of the project is 697.49 kilometers, which is the first automatic welding project implemented by CPECC in overseas with a diameter of 1422 mm and a material of X70 large-caliber high-steel grade natural gas pipeline. During the construction, the project team strives to promote the full coverage of safety responsibilities and safety standards, formulate unified operation standards and specifications for high-risk operations, establish and implement HSE information and resource sharing deployment mechanism, and inspect key parts such as equipment and tools, site warnings, and fire fighting facilities one by one, providing a strong guarantee for the smooth progress of the project. -

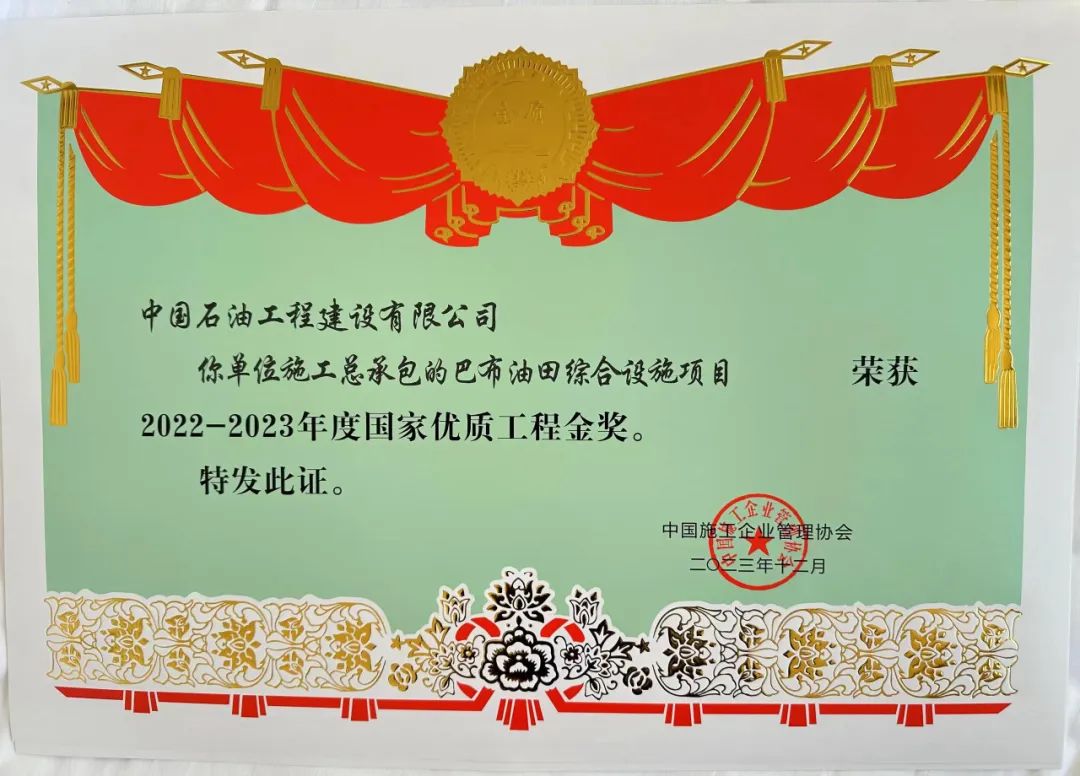

CPECC Gulf Region Company: AiP5 production project advanced with high quality

2024-10-21On October 2, on the MP-156 site of Bab Buhasa Oil Area, Bab Buhasa AiP5 production project of CPECC Gulf Region Company, bulldozers were roaring and earthmoving works were in full swing. "The CPECC team is a reliable partner with strong execution, verbal commitment and results in action." Wael Saleh Almessabi, Vice-president of ADNOC Onshore, spoke highly of the CPECC team's project management and schedule control capabilities.

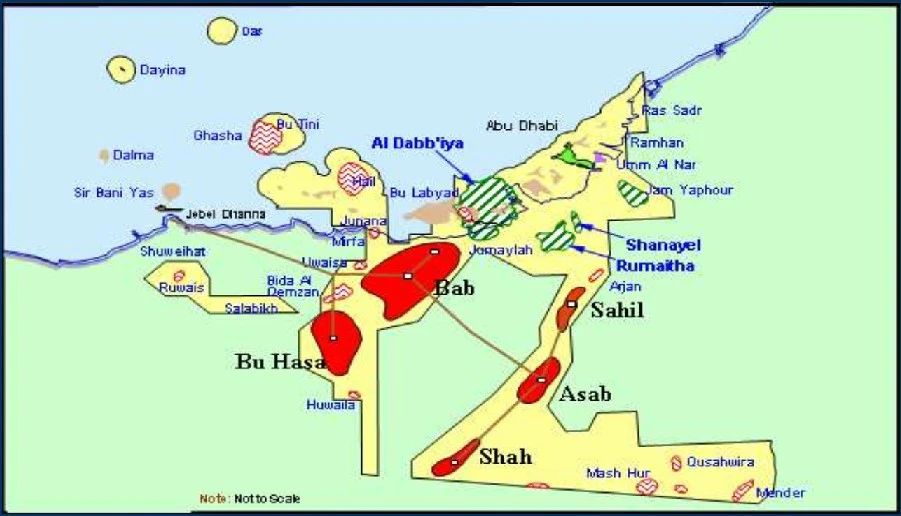

The Bab Buhasa AiP5 production project undertaken by CPECC is ABU Dhabi National Oil Company's (ADNOC) ultra-large surface oil field EPCM project, which is also its breakthrough attempt in the field of AI numerical control. The project covers 3,980 square km in Bab and Buhasa oilfields, including 80 ADNOC Onshore Bab and Buhasa oilfields, the renovation and expansion of nearly 600 oil, water and gas Wells and 1,000 km of new long haul pipelines. Once operational, it will increase production by 116,000 BPD at Bab and 141,500 BPD at Buhasa.

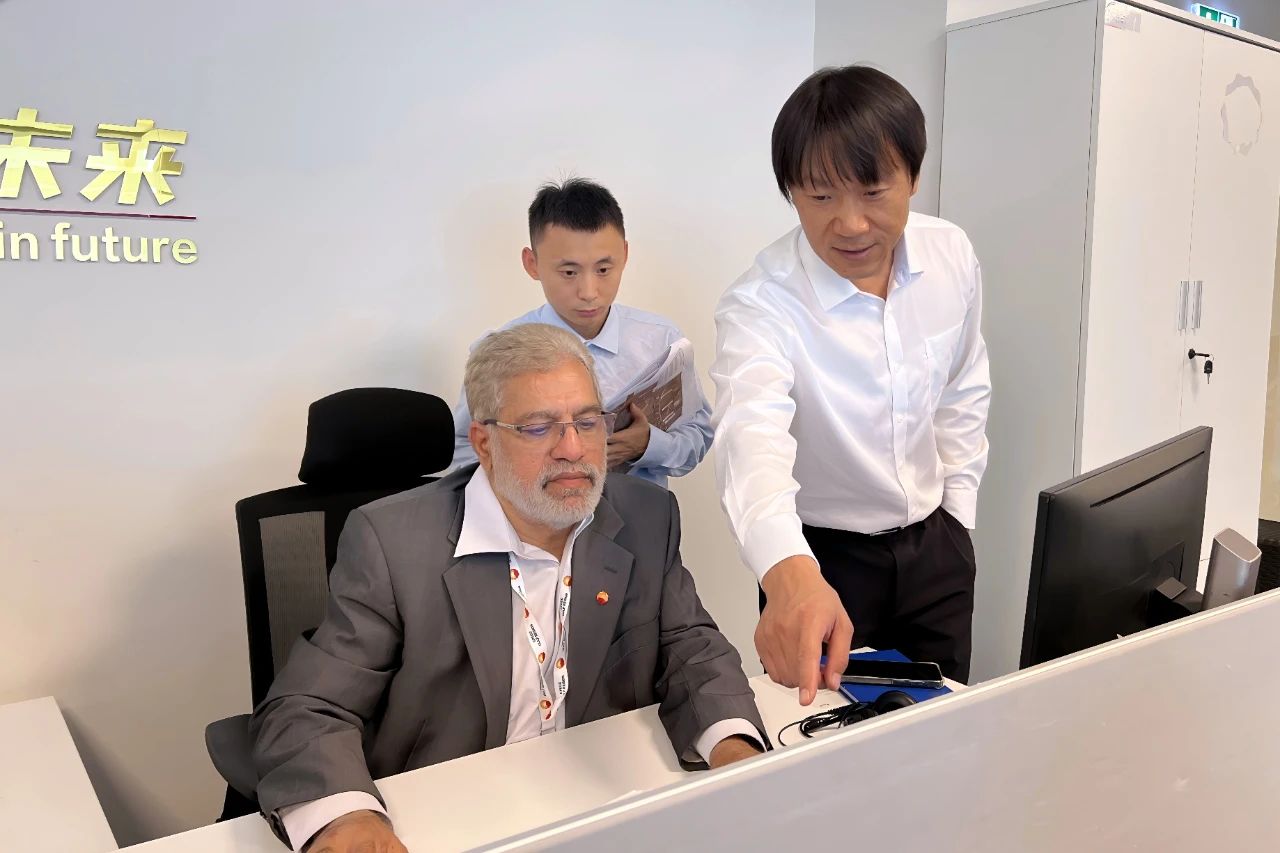

"After the project is completed, we will be able to remotely control Wells hundreds of kilometers away from the central processing station." Mohammed Saleem Abbasi, regional construction manager for the AiP5 project inBuhasa, Gulf Region Company.

Build and share to play a "precise card"

As the centerpiece of ADNOC's P5 plan to increase production to 5 million BPD by 2027, the AiP5 project is based on the new EPCM project model, actively communicating with the owner, constantly exploring innovation, and improving as it is implemented.

Facing the great challenge of full production in 2027, the AiP5 project team accurately grasped the needs of the owners, proposed an innovative concept of "first oil", and worked out a phased and batch production plan with the owners, which not only realized the operation of some Wells more than one year in advance, and created additional economic benefits for the owners. It also has laid a solid foundation for the acceleration of the AiP5 project.

The EPCM model pays more attention to the flexibility and adaptability of the project, and the project team is not only the executor, but also the "technical consultant" who covers the design, procurement, construction and management.

Drawing on CPECC's rich experience in construction organization, the AiP5 project team proposed to divide the construction subcontracting into 9 main parts and select large and powerful subcontracting units with deep qualifications to cooperate. While the owner initially preferred multiple subcontractors to reduce costs, as the project model review and procurement work progressed, the owner gradually recognized the complexity of interfacing with multiple subcontractors and agreed to streamline subcontractors. This decision not only simplifies the business bid evaluation process, improves the overall progress of the project, but also strengthens the control of the project quality.

Strong foundation and solid foundation Draw “concentric circles well”

Compared with EPC projects, EPCM projects lack the detailed guidance of the FEED (Front-End Engineering Design) stage, which is like drawing on a blank sheet of paper and stimulating creativity with only a few keywords. ADNOC's high requirements for process design, especially process simulation and hydraulic calculations, have created unprecedented challenges for the project team.

In order to avoid the adjustment of the design stage affecting the subsequent procurement and model review progress, the project team set up a detailed design team led by the process office of the Beijing Branch to quickly start the preliminary process design, summarize and share experience in time, and accelerate the adaptation process of the new ADNOC Standard (AGES). In addition, the AiP5 project for the first time tried to conduct commercial bid evaluation and order some materials simultaneously when the design accuracy reached 50%, and continued to improve the design drawings and add materials successively. This innovative working mode not only meets the requirements of precision in design, but also improves the efficiency of project operation.

In Bab and Buhasa, two old oil fields that have been in operation for more than 60 years, the AiP5 project faces particularly difficult challenges. The laying of 1000km new long distance pipeline not only solve the technical problems such as large line span and many old pipe lines crossing, but also deal with the interference of external parallel projects. In order to improve efficiency, the project team and the Beijing Branch studied the ADNOC construction procedure documents in depth, identified the key nodes requiring the intervention and coordination of the owner's interface department, and prepared a set of standard flow chart that clearly planned the work content and completion time of each link, and confirmed it with the owner, subcontractors and external parallel project parties. Turn passive work into active collaboration.

"This experience has been both a challenge and a valuable experience, and we now have the ability and confidence to tackle any project or design challenge." Beijing branch Aip5 project design deputy manager Wang Jinjie firmly said.

Gather strength and transform to play the "main melody"

With the rapid development of the ADNOC P5 production increase program, the manpower and material resources in the UAE market are becoming increasingly tight. In order to gain an edge in the fierce market competition, the owner required the AiP5 project team to complete the arduous task of compiling the entire EPCM project pre-planning package within two months. This includes not only project investigation, risk analysis, cost estimation, but also design, procurement, construction and plan management, which runs through the entire project execution cycle, and the workload is huge.

Faced with the challenge, Zhang Fan, manager of AiP5 Project Control Department, led three foreign employees to work together, discuss the details of the plan with the owner during the day, and work overtime at night to adjust the plan package. Within 60 days, more than 2,600 pages of the plan package were completed according to the node. "The owners were amazed at how efficient our team was, and the fact that four of us did what would have taken at least 10 people to do was a huge boost for our entire team." Zhang Fan is full of praise for each member of the project team, he said proudly, "Always ahead of the task, is the firm belief of our team."

Kaleem Aziz, a Pakistani national, has worked for several international companies and joined CPECC in 2017. With his outstanding professional ability, he serves as the interface Manager of Aip5 project. He is busy communicating with people from different countries and different business areas every day to organize and coordinate complex interface interchanges. In the face of endless difficulties on the scene, Kaleem said cheerfully: "Every time I successfully solve the problem, I feel very proud." He compared the Chinese team to a big family, which is closely united and working together to achieve goals.

Over the past year, AiP5 project has not only completed the contract milestone several times ahead of schedule, but also won the trust of the owner with high quality and high standards, and the scope of project work has been extended four times.

From an initial team of a few dozen people to an international team of more than 500 employees from more than 20 countries, AiP5 project has opened up a new situation in the reform, The theme of harmonious development of "respect, equality, openness, inclusiveness and integration" has been played overseas, and built a team full of identity, belonging and cohesion. In promoting transformation and upgrading and exploring the road of digital empowerment, we continue to move forward.

-

Saudi Aramco splashes $25bn on gas field and pipeline expansion, four Chinese firms awarded contracts

2024-07-05Saudi Aramco recently announced that it has signed contracts worth more than $25 billion for the second phase of the Jafurah gas field expansion and the third phase of the expansion of the main gas network.

There are 16 contracts related to the second phase expansion of the Jafurah gas field, with a total value of about $12.4 billion. The content will involve the construction of gas compression facilities and associated pipelines, the expansion of the Jafurah gas plant, including the construction of gas processing units, and the construction of utilities, sulphur and export facilities. Also included is the construction of Aramco's new Riyas Natural Gas Liquids (NGL) frdistillation facility in Jubeir, involving NGL separation units, utilities, storage and export facilities to process NGL received from Jafurah.

There are 15 contracts related to the third phase of the expansion of the main gas network, with a total value of about $8.8 billion. It plans to increase its daily processing capacity to 3.2 billion standard cubic feet by 2028 through the addition of approximately 4,000 kilometers of pipelines and 17 new gas compressor lines.

In the second phase of the Jafurah field expansion project, a joint venture between Sinopec Refining and Chemical Engineering and Spanish petroleum engineering company TR was awarded a contract worth more than $3.3 billion to build a new natural gas condensate (NGL) fractionation facility for the project. In the joint venture, Sinopec has a 35 percent stake and TR has a 65 percent stake.

In addition, in the third phase of the expansion of the main gas system, three Chinese companies have been awarded large EPC contracts. Among them, China Petroleum Engineering Construction Co., Ltd. won the EPC contract of the first phase, worth 9.997 billion yuan; Petrochemical oil Service won the pipeline project contracts for 6 and 7 sections, valued at RMB7.956 billion; Shandong Power Construction won the EPC contract of phase 2.

Among the contracts Aramco has signed are some drilling contracts, also worth billions of dollars.

-

"Belt and Road" project construction poetry - Middle East part III

2024-06-26China Petroleum Engineering Construction Co., Ltd. is a specialized company specializing in surface engineering of oil and gas fields. The company's business orientation: mainly focusing on oil and gas field surface engineering, natural gas liquefaction engineering and offshore oil platform engineering (offshore oil and gas field engineering), supplemented by oil and gas storage and transportation engineering, refining and chemical construction, inspection and maintenance engineering, with full business chain and full life cycle service capabilities, actively developing unconventional oil and gas engineering technology, and moderately developing engineering capabilities in non-oil and gas and non-energy fields. Company development goal: to build an international first-class petroleum engineering company. Since its establishment more than 40 years ago, it has established immortal achievements in the construction of petrochemical engineering at home and abroad. In particular, the implementation of the national "One Belt, One Road" strategy for 10 years, for China's oil to go out, made great contributions. The author had the honor to experience and participate in the management of some projects. During the in-depth work at the grassroots level, he felt the selfless dedication spirit of the grassroots soldiers and the style of tenacious struggle in the face of tough environment. He was deeply moved and created some poems.

After retirement, every time I think of the past days and nights overseas, my heart is still surging. It is now organized into Central Asia, Africa, the Middle East, South America and Russia, and will be published one after another. I have been interested in and writing poetry for about 10 years. There are many problems in my early works, and I sincerely hope that my friends can criticize and correct me.

9, Jiang Chengzi • Ride the wind and waves into the Middle East

---- Grateful for the company's development in the Middle East

(9 January 2019)

The situation in the Middle East, with frequent terrorist attacks, is shocking. Ten years to stick, gradually gradually steady, half the wall appeared; Not afraid of powers, high-end waves, dare to be the first. The exploration process, can sing and weep, touched thousands.

Riding the waves of the Middle East.

Pour passion, gradually calm.

Ten years of fine carving, dare to compete with the great powers.

Often Feihong legend of excellence, the flag is Yan, reputation infinite.

The smoke of the fire cleared and the sound of the tide.

More varied, listen carefully.

Plan as soon as possible.

Rolling energy who ask to take, condensate wisdom, brave climb the peak.

Note: The main business of the company's Middle East branch is distributed in Iraq and Iran; The Iraqi oil engineering market has long been monopolized by Western engineering companies, and it is not easy for companies to survive and grow in Iraq...

10, Qingyu case • Bay wind and waves hard road

---- Message Gulf Company ABU Dhabi Bab Oil Field Project

(10 January 2019)

Based on the bay for more than 10 years, it is difficult to move steadily. The large orders signed last year are being actively promoted and expect to successfully achieve the expected goals.

Rough road in the bay.

And look back, cast frequently.

Going through so much trouble and suffering.

The original intention has not changed, and the plan has not returned.

Smile at the clouds.

Encamped in the desert.

Pen and ink to leave the monument.

I'll throw up the spring silk.

Follow the trend, deep cultivation and fine understanding.

Sound and dance on the other side.

Note: The UAE implements the Western standard system, the project in ABU Dhabi is through the fierce market competition, low price to win the bid, it is not easy to win the big project, it is not easy to make money.

11.Wind into the pine • flying sand boundless yellow

---- Kuwait Wara project

(17 January 2019)

Twenty years ago, I struggled to pay my tuition. Twenty years later, caution returns. This visit to the scene, experience hardships, feeling confident. Write down the words.

The sky is yellow with flying sand.

The sun and moon were without light.

Welding flowers disorderly dance in the crowd, machine sound, high morale.

A brother's heart is not old, but his days are unique.

Once shed tears and returned home temporarily.

A few degrees of hesitation.

For many years, until now, and then change military uniform.

The road ahead is still bumpy, and happiness will be long.

Note: In 1996, the company entered the Kuwaiti petroleum engineering market, and there were no follow-up projects after the completion of the oil gathering station project. In 2017, we won the bid for the Kuwait Wara project and returned to the Kuwaiti market.

12.Seven absolute • dare to call the Middle East green branches

---- A poem written at Beijing airport

(14 October 2019)

When it was cold and snowy in autumn,

To learn to be a great achiever and to fly far away.

Open the land with a mission in mind,

Call it the green branches of the Middle East.

Note: The author is about to fly from Beijing to the Middle East. The Middle East is a desert region, and it is very difficult for trees and grasses to survive.

13, butterfly reading flowers • often high-end grind

---- feeling that the company's gulf engineering construction project is difficult

(19 October 2019)

The bay for a few days, heard and witnessed, mostly talked about, the prospect is worrying, looking back on the way, sigh to deep.

The high end of the grind.

For years, the pain continues.

Crawling in the desert.

Bitter tears and who sued.

A few days to see the sad.

Exhausted thinking, gradually know the cause of error.

Don't forget the wind and rain.

Usher in the world worry-free eyes.

Note: The Gulf project here generally refers to the UAE, Kuwait, Qatar and other projects. High-end refers to the high-end engineering market, which refers to the Middle East and other markets that have long implemented Western standard systems and have been monopolized by Western petroleum engineering companies for a long time

-

Sinopec Oilfield Service Corporation (SSC): Subsidiary signed a RMB7.956 billion project contract with Saudi Aramco

2024-06-11Sinopec Oilfield Service Corporation (SSC) (SH 600871) announced on the evening of 6 June that Sinopec International Petroleum Services Corporation, a wholly-owned subsidiary of Sinopec Oilfield Service Corporation and Saudi Arabian Oil Company (“Saudi Aramco”) entered into a turn-key fixed-price contract for the in-country procurement and construction of Packages 6 and 7 of the Phase 3 Pipeline Project Clusters of the Master Gas System (“MGS”), with the Contract value amounted to SAR5,171,253,587 (approximately RMB7.956 billion, excluding value-added tax).Sinopec Oil Engineering and Construction Corporation, a wholly-owned subsidiary of Sinopec Oilfield Service Corporation, is responsible for the implementation of Packages 6 and 7 pipeline projects under the Contract, mainly undertaking the EPC engineering services for the natural gas long-distance pipeline and its ancillary facilities with a total length of 696 kilometers for both lines. The contractual construction period is 1,275 days.

It is understood that the Saudi Aramco MGS pipeline Phase III project group is the third stage of the development of Saudi Aramco commercial natural gas pipeline project, the main task is to transport natural gas from the eastern Saudi gas field to the central and western coasts of Saudi Arabia, to meet the needs of the rapid development of Saudi national economy, and is a natural gas transmission artery across Saudi Arabia from east to west. The total length of the 6-package and 7-package project is 697.49 kilometers, and the construction content includes the double-line 56-inch buried pipeline and the new supporting facilities along the line.

In recent years, the Sinopec Oil Engineering and Construction Corporation has actively responded to Sinopec's "going out" overseas development strategy and actively responded to the national "Belt and Road" initiative, and has successively conducted projects in Saudi Arabia, Kenya, Uganda, Sudan, Qatar, Algeria and other countries. Contracted Saudi MIP, Uganda Tilenga EPSCC project, Saudi Ministry of Agriculture water purification pipeline project and other projects, and established good cooperative relations with Saudi Aramco, Total and other owners, laid a solid guarantee for the success of the project.

In the next step, the Sinopec Oil Engineering and Construction Corporation will implement the Saudi MGS project as an important starting point to achieve the "three thirds", continue to promote the development of "Saudi regional integration", actively "make bigger and better" Saudi national market, gather wisdom and strength to create a new benchmark for the company's overseas projects, and provide strong support for building a technology leading company and building a first-class engineering construction company.

-

National Natural Gas Group Corporation held the 2024 oil and gas regulation business work conference in Wuhan

2024-03-29Recently, the National Natural Gas Group Corporation held the 2024 oil and gas regulation business work conference in Wuhan, in-depth implementation of the Group's 2024 work conference and the deployment of the Party building work conference, a systematic summary of the work in 2023, analysis of the situation and problems faced, and arrangement of key work in 2024. Mobilize the majority of cadres and employees to unite and work hard to provide a strong guarantee for the Group company to accelerate the construction of a world-class enterprise and achieve high-quality development. Jiang Changliang, deputy general manager of the Group and member of the Party Group, attended the meeting and made a concluding speech.

Jiang Changliang pointed out that in 2023, under the correct leadership of the Party Group of the Group company, all cadres and employees of the control front resolutely implemented the overall strategy of the Group company's "five adherence" and "five hard work" party building deployment, fully implemented the requirements of "pipe network reform and regulation first", completed the reform of the "1+6+1" control system with high quality, and deeply promoted the construction of "six unified". The value of the "five functions" of the control system was highlighted, the goal of centralized and unified management of the control business was fully realized, the oil and gas transmission volume reached a new high, the safety production achieved the goal of "six zeros and six hundred percent", the energy consumption of the unit pipeline transportation decreased steadily, and new breakthroughs were made in scientific and technological innovation, giving full play to the role of the "backbone" of the pipe network operation command, and carrying out the "Four modernizations" reform for the Group. Accelerating the construction of "one national network" has laid a solid foundation.

Jiang Changliang stressed that it is necessary to unify the thinking and understanding, strengthen confidence, seize the momentum, constantly gather the high-quality development of oil and gas regulation, make every effort to promote the formation of a national oil and gas dispatching center, hold the bottom line of safety, and strengthen support for promoting the "Four modernizations" reform and high-quality development of the group. It is necessary to make first-class and precise efforts, deepen the management of regulation and control business, practice high-quality development skills, adhere to reform and innovation, plan the step-by-step path of intelligent regulation from a high starting point, accelerate the research and development and application of intelligent regulation and control technology, and make every effort to create the regulation capacity matching the world-class enterprises and the world's leading oil and gas regulation and control system. It is necessary to strengthen the leadership of party building, seek truth and pragmatism, forge ahead with determination, comprehensively forge the control iron army team that can handle the high-quality development responsibility of the Group company, deeply implement the requirements of Secretary Zhang Wei to build the control front into "the expert in the expert, the iron army in the iron army", activate the control business with high-quality party building and develop the "red engine", and deepen the dispatching iron Army culture. Deepen the professional and professional construction of dispatch, deepen and expand the "five actions" of the construction of the regulatory Iron Army team, optimize the scheduling assessment mechanism, and accelerate the forging of a regulatory talent team that can meet the heavy responsibility.

Group company general manager assistant Li Wendong attended the meeting. Central China Company representative, Party Secretary Yi Lin attended and delivered a speech. Oil and gas control center company representative, Party secretary Li Fengxue, director Qi Guocheng presided over the meeting. Qi Guocheng for the regulation business 2023 annual work report, the relevant units for the regulation of iron army cultural construction report, intelligent regulation and control exploration and practice report, to share the experience of regulation and control operation, participants around the safe operation, regulation and control of iron army shaping content to exchange speeches and symposiums. -

National Pipe Network Group signed a strategic cooperation framework agreement with Tianjin

2024-03-07Recently, the Tianjin Municipal People's Government signed a strategic cooperation framework agreement with the National Petroleum and Natural Gas Pipeline Network Group Co., LTD. Tianjin Municipal Party Committee Secretary Chen Miner, deputy secretary of the Municipal Party Committee, Mayor Zhang Gong and National Pipe Network Group Chairman, Party Group secretary Zhang Wei, general manager, deputy Party Group secretary He Zhongwen and their delegation discussed and witnessed the signing.

Chen Miner and Zhang Gong, on behalf of the Tianjin Municipal Party Committee and the Tianjin Municipal Government, welcome Zhang Wei and He Zhongwen to Tianjin to deepen cooperation. Energy security and security concern the national economy and people's livelihood. The State Pipeline Network Group is the largest specialized energy infrastructure operator in China and maintains a good cooperative relationship with Tianjin. It is hoped that the two sides will take this signing as a new starting point to strengthen docking and communication, make good use of existing resources, deepen practical cooperation in science and technology research and development, new energy storage and other fields, and jointly build a regional energy hub. We will continue to improve supporting services, create a good environment for the development of National pipe Network Group in Tianjin, and strive to achieve mutual benefit and common development.

Zhang Wei introduced the development of the National pipe network Group and its business development in Tianjin, and thanked the Tianjin Municipal Committee and government for their strong support.

According to the agreement, the two sides will carry out in-depth cooperation in the development of strategic emerging industries, scientific and technological research and development, energy infrastructure construction, and gas supply guarantee.